Bahmuller

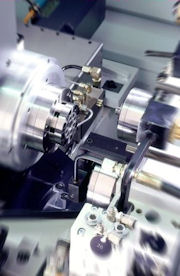

Internal & External Cylindrical Grinding Machines

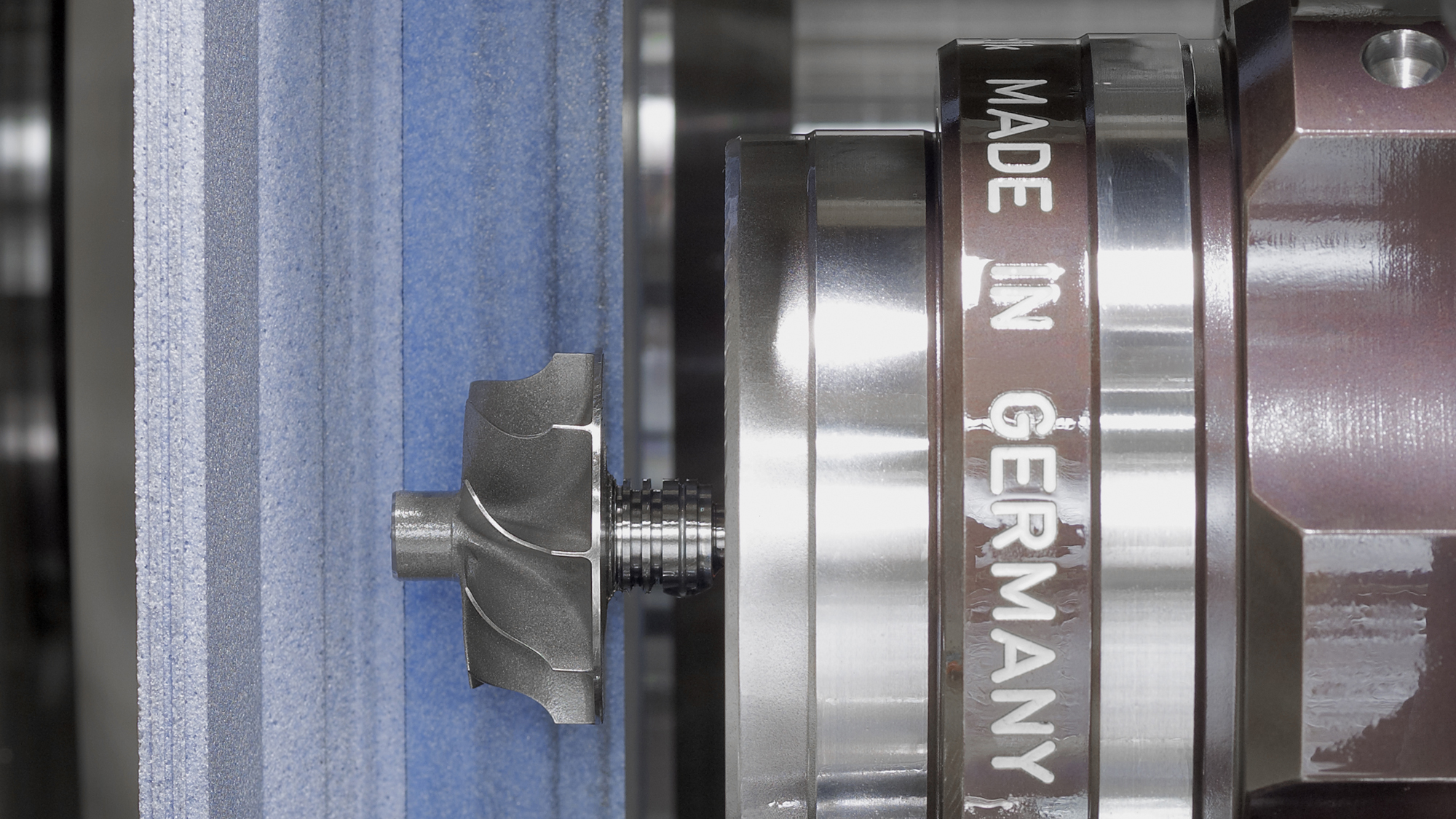

Founded in 1945 in Pluederhausen, Bahmuller produces internal, external, and combined universal grinding machines of the very highest precision.

Bahmuller is an industry leading machine tool manufacturer providing turn-key production solutions and specialises in the development of ultra-modern technologies for high-precision grinding systems for diesel injection units, hydraulics, turbo chargers and other highly precise mass-produced components.

The wide range of internal, external, and combined grinding machines is successfully used worldwide and its Bahmuller’s continuous mission and main focus to provide all customers with leading edge technology for their demanding manufacturing requirements.

The Bahmuller QUBE is a truly revolutionary high performance and very economical grinding machine designed to be perfectly suited for the single-process machining of sensitive fuel injection- components and similar parts that do not require multi-axes processing. By placing the workpiece above the internal or external grinding wheel the greatest possible efficiency is provided within the smallest floor space. Bahmullers focus remains attaining the lowest possible component production costs for its customers. QUBE machines offer end users substantial savings on cycle times due to the very short distances that the machining axis have to travel and several QUBE machines may be linked together for seamless and combined machining operations. To download information on the new QUBE machine please Click Here.

Bahmuller has now entered into the machine tool loader market with its new FEED loader. These can be specified with single or double drawers and/or with palletizers and stacking modules. Process modules mounted within the FEED loaders include for operations such as part measurement, labelling, cleaning, brush deburring, polishing and marking etc.

Bahmuller also offer highly flexible production solutions for the manufacture of turbo charger shafts and wheels. We have created a special customer only access page for turbo shaft manufactures to view videos and to understand the many production concepts offered by Bahmuller. These range from single machines for just shaft, just wheel, or both grinding applications to larger "twinner" machines that have the same flexibility but offer double the output.

Bahmullers I-PRO range of internal grinders may be specified with between 1 and 6 internal grinding spindles and for mass production purposes two independent cross slide systems can be employed to create two machines in one. This results in a reduced footprint with a lower overall capital investment whilst obtaining double the output! Furthermore, if one part of the machine is down for re-setting or maintenance this can be carried out whilst the other "half" of the double machine continues to produce components. Special high precision clamping systems are used to guarantee incredibly tight tolerances such as concentricity to 0.3um and under.

The X-PRO range of external cylindrical grinding machines is designed for producing very high precision parts such as those needed for the fuel injection and turbo-charged industries with roundness values of under 0.5um being generated. Various clamping and tailstock designs allow for high flexibility. Manual, motor driven, or piezo technologies are all proven ways to adjust the tailstock for taper compensation. In case of any problems with small parts suffering from deflection during high speed grinding Bahmullers piezo technology compensates for this automatically. Close-loop feedback for process-controlled adjustments and data exchange between the X-PRO machine and pre-process, in-process or post-process measuring systems and automation is standard.

Bahmuller also offer C-PRO universal combined grinding machines for external and internal cylindrical grinding with multiple CNC axes set-up for the simultaneous grinding of internal and external part features with a single automatic operation on the same machine. Bahmuller incorporates hydrodynamic and hydrostatic guide systems as part of the machine construction and the use of absolute linear encoders (glass scales) as standard allows exact axis positioning within 0.0001mm. Multiple grinding stations are mounted on top of the axes for processing of several features in a single clamping and the external grinding spindle head can be equipped with a single or a multi-stacked configuration. Finally, the slides for internal grinding can be fitted with 1 or 2 high-frequency grinding spindles.

Many production engineers simply do not believe the output and precision that Bahmuller machines guarantee. Imagine grinding machines with not one but with up to 6 grinding spindles and programmable axis increments of 0.1um and you will start to see the vision.

Visions of Precision from Bahmuller!

References

Our range of machines is supplied to numerous companies all around the world and the leaders in industry use these to great affect.

We have many thousands of worldwide references but customers that we have supplied equipment to here in the UK include, amongst others: